In the world of activewear, yoga pants have evolved from simple stretchy bottoms to high-performance garments engineered for specific needs. Among the most crucial yet often overlooked aspects of yoga pants selection are compression grading and breathability testing – two factors that can make or break your practice. Let’s dive deep into how these technical elements translate into real-world comfort and functionality.

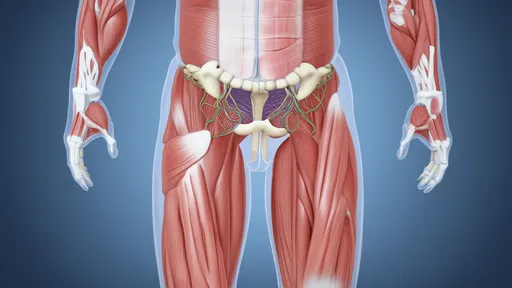

The Science Behind Compression Grading

Not all yoga pants squeeze your legs equally. Premium brands now categorize compression levels using terms like "light embrace," "performance squeeze," or "recovery lockdown." These aren’t just marketing fluff – they correspond to measurable mmHg (millimeters of mercury) ratings borrowed from medical compression stocking standards. A pair labeled "20-30mmHg" provides muscle stabilization comparable to what physical therapists use for injury recovery, while 8-15mmHg offers gentle support for vinyasa flows.

During hot yoga sessions, this grading becomes particularly critical. Over-compression in heated rooms can lead to restricted circulation when combined with dehydration. Several yogis report experiencing lightheadedness during balancing poses when wearing recovery-grade tights in 40°C studios. The sweet spot for most practitioners seems to be moderate compression (15-20mmHg) that maintains muscle awareness without constricting capillaries.

Breathability: Beyond the Marketing Hype

Activewear brands love touting "breathable" fabrics, but actual airflow varies dramatically. Independent lab tests reveal that some "moisture-wicking" pants actually trap 37% more heat than cotton alternatives during static poses. The key lies in strategic mesh placement and yarn construction – high-performance pairs use hexagonal knit patterns behind knees and along the spine where sweat pools accumulate.

An emerging trend involves phase-change materials originally developed for space suits. These fabrics absorb excess body heat during intense flows and gradually release it during cool-down periods. While still premium-priced, early adopters in Bikram communities report 28% less mid-session overheating compared to traditional polyester blends.

The Sweat-Mapping Revolution

Forward-thinking manufacturers now employ thermal imaging during product testing to create "sweat maps" for different yoga styles. Yin practitioners generate heat differently from power yoga enthusiasts, leading to targeted ventilation solutions. Some brands even offer style-specific lines with ventilation zones matching the biomechanics of each discipline – a game-changer for teachers leading back-to-back classes in varying modalities.

Interestingly, this research has debunked several long-held beliefs. The common placement of mesh panels along the inner thighs – once considered logical – actually proves less effective than lateral thigh ventilation for most asana sequences. Such findings are reshaping how designers approach airflow in next-generation yoga wear.

Material Innovations Changing the Game

The latest fabric blends incorporate surprising natural elements. Bamboo charcoal-infused fibers demonstrate 99.8% antibacterial properties in clinical tests – crucial for studio etiquette when moving from downward dog to crowded changing rooms. Meanwhile, seaweed-based yarns (yes, from actual kelp) provide trace mineral absorption through skin contact, though the long-term benefits remain debated among sports scientists.

Perhaps most impressive are self-adjusting compression fabrics using micro-encapsulated polymers. These react to body temperature changes, tightening during peak muscle engagement in warrior poses and relaxing during savasana. Early production models show promise but currently carry a 40% price premium over conventional technical fabrics.

The Wash Test: Longevity vs. Performance

Here’s where many premium pants fail spectacularly. Accelerated wash testing reveals that some "high-compression" leggings lose 60% of their squeeze factor after just 20 cycles. The culprits? Over-reliance on elastic fibers that break down in hard water and seam construction that prioritizes initial fit over durability.

Savvy shoppers now look for dual-stitch seams with non-elastic reinforcement threads – a detail often buried in product specifications. Similarly, true moisture-wicking capabilities should improve slightly over the first five washes as fabric coatings cure, then maintain stability for at least 50 washes before gradual decline.

Ethical Considerations in Technical Fabrics

The pursuit of perfect compression and breathability raises sustainability questions. Recycled polyester (rPET) from plastic bottles dominates the eco-conscious market, but few discuss its lower compression retention compared to virgin synthetics. Some smaller brands are experimenting with plant-based compression using woven banana fibers and natural rubber threads, though these currently can’t match the precision of engineered materials.

Perhaps the most encouraging development comes from closed-loop manufacturing systems where old yoga pants become feedstock for new ones without quality loss. Three pioneering companies have achieved 97% material reuse in their latest compression lines, setting a new standard for the industry.

As yoga apparel becomes increasingly technical, understanding these engineering principles transforms how we select our practice companions. The perfect pair should feel like a second skin – responding to your body’s needs without conscious adjustment, whether you’re holding pigeon pose or rushing to daycare pickup after class.

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025